If you are thinking about applying a fresh coat of paint to your room or your house, you may need to use a paint sprayer. But do you need an air compressor to use a paint sprayer? We researched this question for you and have an answer.

Not all paint sprayers need an air compressor. The ones that do are usually used by professionals. If you need to paint a wall or a room in your house, then an airless paint sprayer will suffice.

In this article, we will further explain the topic on hand as well as what to look for when buying an air compressor and how to maintain it. Additionally, you will learn the benefits of using an airless paint sprayer if you don't feel like getting an air compressor. Continue reading to find out more.

Does A Paint Sprayer Need An Air Compressor?

Not all paint sprayers need an air compressor, as some have a mechanism that replicates the function of an air compressor. But that does not mean that an airless paint sprayer is superior to a paint sprayer that needs an air compressor.

A paint sprayer that uses an air compressor is generally larger and can hold more paint. This allows you to work longer without having to worry about refilling. This type of paint sprayer can cover a larger surface area than an airless paint sprayer.

These reasons contribute to why most professionals use paint sprayers with an air compressor. It's just more efficient for them to use something bigger and more powerful when doing their work.

If you're looking to paint a portion of your home, you will find that an airless paint sprayer is more than enough.

What To Look For When Buying An Air Compressor?

We may include affiliate links and curated AI content to highlight top design styles.

If you're keen on using a paint sprayer that requires an air compressor, there are some things that you need to be aware of. In this section, you will learn what to look out for when buying an air compressor:

Volume

When it comes to air compressors, you need to determine how much air they can produce. It uses the term cubic feet per minute when referring to the quantity of air produced, or CFM.

To determine how much CFM you need from an air compressor, check your paint sprayer for specifications. Usually, the manufacturer will indicate the required CFM. You can also check the owner's manual or look it up online.

Once you know the required CFM, you need to buy an air compressor with a slightly higher CFM. This is to ensure that your paint sprayer is working optimally and efficiently. Getting an air compressor that has the same CFM as your paint sprayer will produce uneven results because it can't always maintain the same CFM the longer you work.

Pressure

When it comes to air sprayers, they are usually classified into two types based on the volume of compressed air that they use. These two are high volume low pressure (HVLP) paint sprayers and low volume low, pressure (LVLP) paint sprayers.

While both variants require different amounts of compressed air, the pressure they need is the same. It just takes a little pressure for a paint sprayer, as the recommended amount is around 28 pounds per square inch (PSI).

Tank Size

The bigger the tank of an air compressor, the better the result. When buying one, you generally want a model that can hold 30 gallons of compressed air or more.

Note that a larger tank doesn't mean that the compressor has a high CFM output. So, make sure to double-check the CFM rating before settling on one.

Check out this air compressor on Amazon.

What Are The Benefits Of Using An Airless Paint Sprayer?

If an air compressor is too big for your home and you want to upgrade from using paint rollers and paint brushes, consider buying an airless paint sprayer. It has several benefits that will make you ditch your old painting tools.

For one, it is easy to store and use. It doesn't require much cleaning compared to traditional rollers and brushes, and it will hold up longer, so you can use it for multiple projects over a few years to decades.

An airless paint sprayer also provides ample painting coverage, leading to a smoother and more consistent finish. It only takes half the time or less to complete a project as opposed to using traditional methods.

It's also cost-effective. Unlike traditional methods such as a roller or a brush, paint won't drip off and splatter everywhere. You'll use the right amount of paint each time, and it will come out evenly.

Check out this electric paint sprayer on Amazon.

Best Paint To Use In An Airless Paint Sprayer

When choosing what paint to use, you don't need to worry, as almost every type works with a sprayer—unless, of course, the manufacturer states explicitly that you shouldn't use it.

Instead, it's more about how thin the paint is. Thin paint won't clog up the nozzle of the air sprayer. The thicker the paint, the harder it is to come out. When that happens, it won't produce consistent results when spraying.

All you need to do is add water to thin the paint. The ratio wholly depends on the desired viscosity of the paint. Most manufacturers add the correct ratio when thinning paint in their products, so you can use that as a guide.

However, be careful when thinning paint. For example, acrylic paint does not require a lot of water for thinning because it is a water-based paint. Adding too much water can keep the paint from bonding properly to the surface and lead to flaking.

For oil-based paint, adding just water is not enough in some cases. You will need a thinner or something similar to help dilute its viscosity for it to work in your air sprayer. Check the packaging or owner's manual beforehand for any special instructions from the manufacturer.

How To Maintain An Air Compressor

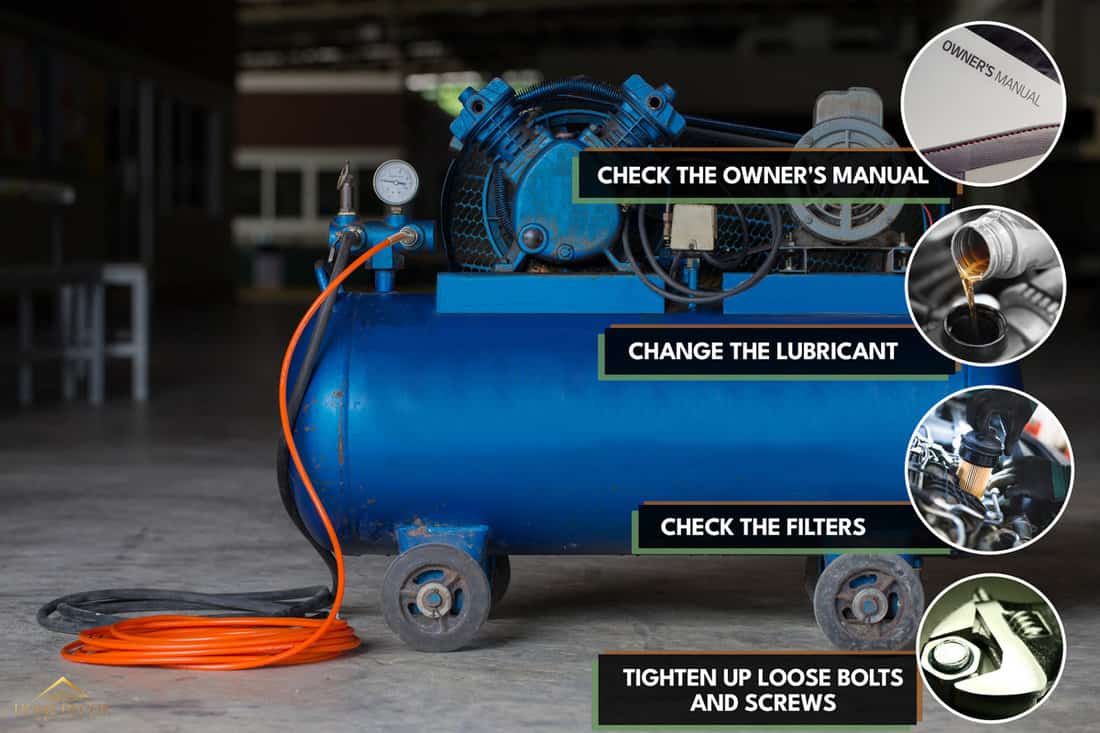

Like most equipment, an air compressor must be well maintained. In this section, you will learn some tips and tricks to do just that.

Check The Owner's Manual

First and foremost, you need to read the owner's manual, especially if it's your first time owning an air compressor. By doing this, you can avoid making simple mistakes that could harm the machine.

Not only that, but most companies detail what it is that you need to do when it comes to regularly maintaining your air compressor in their manuals. So don't throw the manual away and keep it in a safe place for future use.

Change The Lubricant

Ensure an air compressor's internal parts and joints have enough lubrication. This eases the tension between the metal parts and prevents corrosion. The last thing you want is rust to form and eat through the machine.

Additionally, you need to replace the lubricant every three to six months. If you let it linger for too long, it will lose its viscous properties and corrode.

Check The Filters

An air compressor has a couple of filters that need to be changed regularly to ensure air quality.

The first of these filters is the air filter. As you may already know, this filter is responsible for keeping impurities like dirt and other particles separated from the compressed air. Make sure to change or replace this filter based on how often you use the air compressor.

The second filter is the oil filter. The last thing you want is oil getting into the machine and leaking out along with the compressed air. You should check the oil filter regularly, at least once a week, to ensure that oil is not spilling out of the machine.

When you reach between 4,000 and 8,000 hours of usage time with the air compressor, you should change the oil filter. Also, if the filter starts mucking up with too much oil, you should replace it.

Tighten Up Loose Bolts And Screws

The more you use your air compressor, the higher the chance for bolts and screws to loosen up. That's because of the vibrations device produces whenever you turn it on.

You should check the bolts and screws after every use. Tighten them up when necessary to keep your air compressor in good working condition.

To Wrap Up

Not all paint sprayers need an air compressor. But for those that do, you need to first figure out what you want from an air compressor if you're planning on buying one. You can also opt for an airless paint sprayer, which should suffice for most home painting projects.

If you found this article helpful, check out the links below for related topics:

How To Use A Craftsman Air Compressor [Step By Step Instructions]